Introduction

EN 43B is a medium carbon steel grade known for its high tensile strength, good wear resistance, and excellent toughness. Typically used for springs and applications requiring high fatigue strength, EN 43B is suitable for oil hardening and tempering. This material is part of the British EN 100 series and offers a good balance of strength, ductility, and machinability, making it highly versatile for a range of engineering purposes.

Properties of EN 43B Grade:

- Good tensile and yield strength

- High fatigue and wear resistance

- Moderate machinability

- Good weldability with proper procedures

- Capable of being oil hardened and tempered

- Suitable for heavy-duty springs and automotive components

- Good ductility after appropriate heat treatment

Uses/Applications of EN 43B Grade:

- Manufacture of automotive leaf springs

- Coil springs, conical springs, and heavy-duty suspension springs

- Agricultural machinery components

- Mining and construction machinery parts

- General engineering and structural applications

- Industrial tools and machine parts requiring high strength

- Tension rods, brackets, and fasteners

Chemical Composition (Typical):

| Element | Content (%) |

| Carbon (C) | 0.45 max |

| Manganese (Mn) | 0.50 – 0.90 |

| Silicon (Si) | 0.10 – 0.40 |

| Phosphorus (P) | ≤ 0.05 |

| Sulfur (S) | ≤ 0.05 |

| Iron (Fe) | Balance |

Mechanical Properties (Typical):

| Property | Value |

| Tensile Strength | 600 – 800 MPa (after heat treatment) |

| Yield Strength (0.2% Proof Stress) | ≥ 400 MPa |

| Elongation (in 50 mm gauge length) | ≥ 14% |

| Impact Value (Charpy V-Notch at room temperature) | ≥ 27 Joules |

| Hardness (Brinell Hardness) | 190 – 260 HB (after heat treatment) |

Physical Properties:

| Property | Value |

| Density | 7.85 g/cm³ |

| Modulus of Elasticity | 210 GPa |

| Thermal Conductivity | ~45-50 W/m·K |

| Specific Heat Capacity | ~460 J/kg·K |

| Electrical Resistivity | ~0.15 µΩ·m |

Forging:

Forging operations are typically conducted between 1100°C and 850°C:

- Start forging at around 1100°C.

- Finish forging at around 850°C.

- After forging, slow cooling under cover or in a furnace is recommended to prevent surface cracking.

Heat Treatment:

EN 43B is usually supplied in an untreated condition but can undergo various heat treatments to enhance properties:

- Normalizing: Heat to 840°C – 870°C and cool in air.

- Hardening: Heat to 820°C – 850°C, quench in oil.

Dimensional Tolerances:

Manufactured according to standard tolerances:

- Hot Rolled Bars: EN 10058, EN 10059 standards.

- Cold Drawn Bright Bars: EN 10277 for tighter dimensional control and surface finish.

Specific tolerances can be supplied as per customer requirements for precision applications.

- Tempering: Reheat to 400°C – 680°C depending on required mechanical properties and cool in air.

Typical heat-treated condition: Hardened and tempered to achieve a tensile strength of 600-800 MPa.

Machinability:

EN 43B offers moderate machinability:

- Better machinability in a normalized condition compared to hardened and tempered conditions.

- Use of carbide or high-speed steel cutting tools is recommended.

Corrosion Resistance:

- Low inherent corrosion resistance.

- Rusts in humid or marine environments without protective treatment.

- Surface protection such as painting, galvanizing, or oiling is recommended for corrosion-prone environments.

- Proper lubrication and cooling enhance tool life and surface finish.

- Machinability rating is approximately 55% – 60% compared to free-machining steels.

Weldability:

- EN 43B is weldable with care.

- Preheating to approximately 150°C – 250°C may be necessary depending on section thickness.

- Post-weld stress relieving is advised to reduce residual stresses.

- Suitable welding methods: MIG, TIG, SMAW, SAW using appropriate low-hydrogen electrodes.

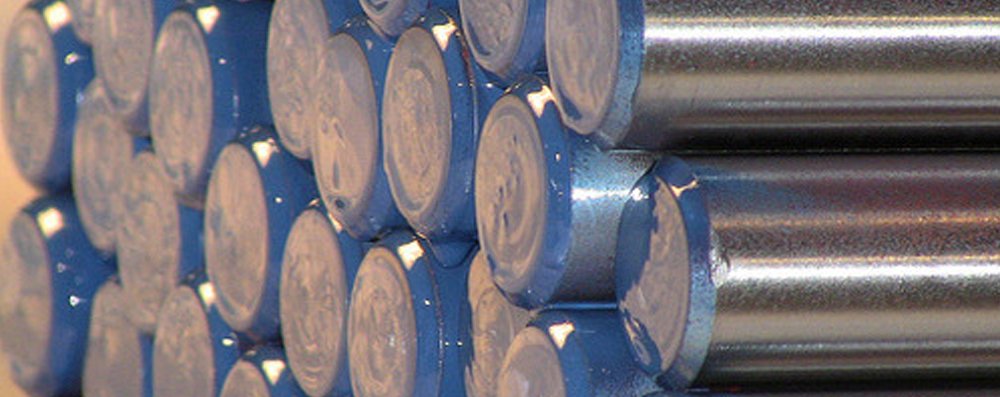

Available Form:

- Hot Rolled Round Bars

- Cold Drawn Bright Bars (Round, Square, Flat)

- Forged Bars

- Hexagonal Bars

- Flats and Plates (special order)

- Custom cut lengths available upon request

Finished products are available in black, bright, normalized, or annealed conditions.

Conclusion:

EN 43B carbon steel bar is a dependable choice for applications requiring high strength, moderate toughness, and excellent fatigue resistance. Its versatility in heat treatment and forging processes makes it ideal for the production of springs, automotive parts, and heavy-duty machinery components. With proper surface protection and controlled welding practices, EN 43B delivers robust performance across diverse industrial sectors.

Related Products :20C8, ASTM A36, 20MN2, 55C8, 40C8, C45, ASTM SA-105, C50, C20, C55, EN3B, C55 Mn2, C60, C45, EN9, EN8, EN8D, IS 2062, EN43B, S355J2G3, S40C, SAE 1010, SAE 1018, ST52.3, 20MN2, Maps