Introduction

AISI 52100 is a high-carbon chromium alloy steel known for its excellent strength, hardness, and wear resistance. Widely used for bearing applications, it provides outstanding fatigue strength and high resistance to abrasion. With high cleanliness and uniformity, AISI 52100 delivers superior rolling contact fatigue performance, making it the material of choice for precision components and mechanical parts.

Properties of the Grade:

- Machinery parts: Shafts, gears, axles, rotating parts.

- Automotive: Connecting rods, levers.

- Agricultural Equipment: Components subjected to moderate stress.

- Structural components: Beams, sleeves, wheels, rings.

- Fasteners: Screws, nuts, washers.

- Seamless steel pipes.

Uses/Applications of the Grade:

- Ball and roller bearings

- Bearing races

- Automotive components (gears, shafts, and fasteners)

- Aerospace parts

- Precision instruments

- High-stress machine components

- Hand tools and cutting tools

- Railway axle journals

Chemical Composition:

| Element | Content (%) |

| Carbon (C) | 0.98 – 1.10 |

| Manganese (Mn) | 0.25 – 0.45 |

| Silicon (Si) | 0.15 – 0.35 |

| Chromium (Cr) | 1.30 – 1.60 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

Chemical Composition:

(Typical after Heat Treatment)

| Property | Typical Value |

| Tensile Strength | 850 – 1000 MPa |

| Yield Strength | ≥ 670 MPa |

| Elongation | ≥ 8% |

| Reduction of Area | ≥ 30% |

| Hardness (Annealed) | 187 – 229 HB |

| Hardness (Hardened) | 60 – 66 HRC |

| Fatigue Strength (Rotating) | High |

Physical Properties:

| Property | Typical Value |

| Density | 7.81 g/cm³ |

| Modulus of Elasticity (Elastic Modulus) | 210 GPa |

| Thermal Conductivity | 46.6 W/m·K |

| Specific Heat Capacity | 460 J/kg·K |

| Coefficient of Thermal Expansion | 10.4 × 10⁻⁶ /°C |

Forging:

Forging Temperature Range: 850°C – 1200°C

Forging Procedure:

- Preheat slowly and uniformly.

- Final forging should not be below 850°C.

- Cool slowly in furnace or dry ash to avoid surface cracking.

Heat Treatment:

-

Annealing:

- Heat to 760°C – 800°C.

- Furnace cool slowly to obtain a hardness of around 187–229 HB.

-

Hardening:

- Heat to 800°C – 840°C.

- Oil quench immediately.

-

Tempering:

- Temper at 150°C – 200°C for desired hardness and toughness balance.

- Higher tempering temperatures will lower hardness but improve toughness.

Dimensional Tolerances:

- As per ASTM A295 and A322 standards for bar products.

- Bright drawn and turned bars: h8 to h11 tolerance classes available.

- Ground and polished bars available for tighter tolerances.

Machinability:

- Good machinability in annealed condition.

- Machinability rating around 50% relative to free-cutting steels (e.g., AISI 1112).

- Recommended to machine in softened condition before final heat treatment.

Corrosion Resistance:

- Limited corrosion resistance; it is not a stainless steel.

- Suitable for lubricated or sealed environments.

- Surface treatments (plating, coating) or protective oils are advised for exposed environments.

Weldability:

Not recommended for conventional welding due to risk of cracking.

If necessary, welding should be carried out under controlled conditions:

- Preheat to 200°C – 300°C.

- Post-weld annealing/stress relieving mandatory.

Available Form:

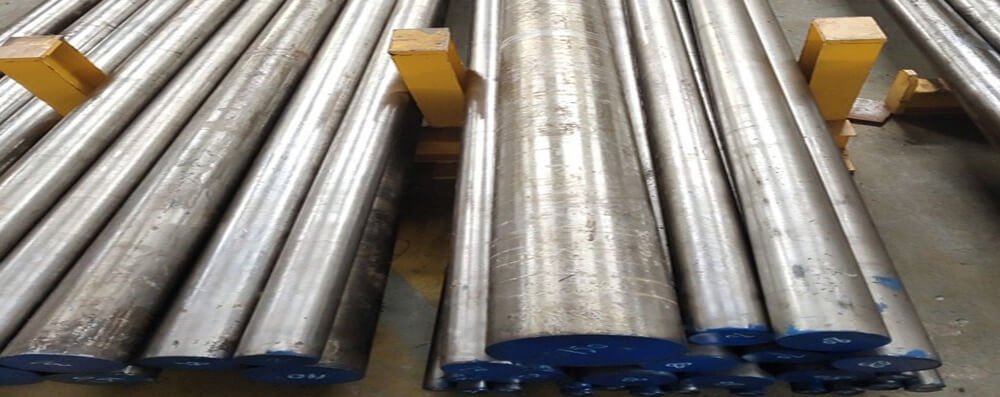

AISI 52100 Alloy Steel Bars are available as:

- Hot Rolled Bars

- Cold Drawn Bars

- Peeled & Ground Bars

- Forged Bars

- Turned and Polished Bars

- Custom Cut-to-Length Pieces

- Annealed, Hardened & Tempered Forms

Conclusion:

AISI 52100 is a premium high-carbon chromium alloy steel offering outstanding hardness, wear resistance, and fatigue strength. It is an ideal choice for bearing applications and precision components where performance reliability under high loads and cyclic stresses is critical. With proper heat treatment and surface protection, it delivers long service life and optimal mechanical properties for demanding applications.

Related Products : 16MnCr5, EN19, 42CrMo4, 20MnCr5, EN353, EN31, EN24, EN47, EN41B, SAE4140, SAE52100, SAE 8620, SCM420, EN36C, Maps